SpecialFour line horizontal annealing furnace, each line can be annealed independentlyFull automatic program control. The working speed of the wire during annealing and the shape of the wire arrangeme

Features:

Four line horizontal annealing furnace, each line can be annealed independently

Full automatic program control. The working speed of the wire during annealing and the shape of the wire arrangemenare analyzed(straight row, ball row and cable density) can be set on the touch screen interface.

Servo drive and control are adopted for winding and winding drive and pay off drive

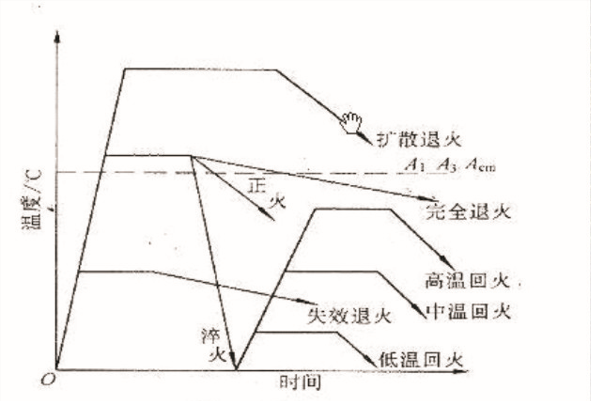

Annealing temperature can be set according to process requirements, and temperature PiD control

Using ad operation tension control, full digital operation

Take up to realize soft start and stop

Wireless shutdown alarm

Independent cleaning device,degreasing and decontamination

The outlet can be heated and baked, and the temperature can be controlled

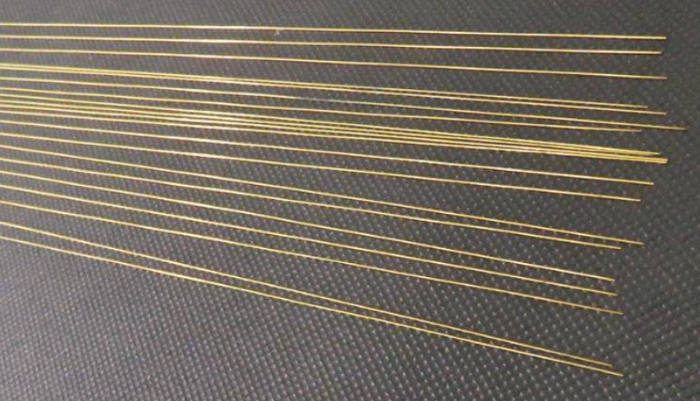

The whole machineis suitable for annealing of variousprecious metal filaments and ultra-fine wires.

Machine specification:

Annealing temperature Max:850℃

Annealing wire diameter: 0.010~0.050mm

Annealing speed: 0~200m/min (Adjustable)

Tension range: 0.5~20g

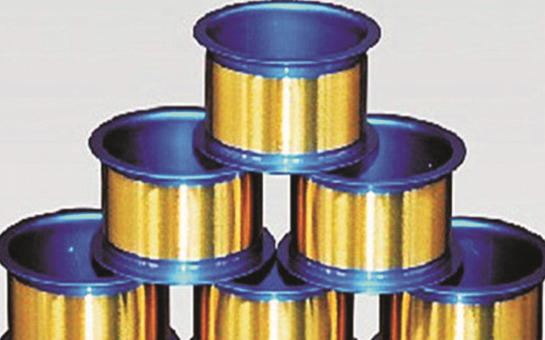

Spool diameter: 50 mm, 80 mm and 100 mm are available

Cable swing: 70mm

Total power: 10KW

Total power supply: 380V,50HZ

Control mode: PLC touch screen automatic control

Temperature control mode: PID automatic calculus control

Control software: Cyx-p02.Independent research and development

Number of withdrawal lines: 4-wire independent

Temperature control area: 2 groups, 6 channels

Wind blade: 2 groups

Vacuum cleaning: 4 routes

Outlet cleaning: 2routes

Outlet baking: 2 groups of independent control

Machine size: 2400*900*1250mm